Energy Density - The Key To Forecasting Electric Flight

In my last article we looked at the first-movers putting a 6-seat electric aircraft into the air. If we step back from that milestone, we can see the slope of a capability curve gaining definition. In just 15 years, electric flight has gone from 2-seat gliders to 6–9 seat aircraft. The question now isn’t if electric airplanes can fly, but how much they can scale.

Could we ever see a widebody flying JFK–NRT on batteries alone? The answer lives and dies on one figure: energy density.

By tracing how this number can evolve, and how production aircraft can accelerate it, we can forecast what comes next. But before looking forward, it’s worth asking: why bother with electric airplanes at all?

Why Electric Flight Matters

Stating the obvious: electric airplanes mean zero-emission flight. That fact tends to dominate the conversation, but it risks overshadowing the economics that will actually drive adoption. Electric aircraft matter because they bring three structural advantages:

Lower operating costs: Electricity costs a fraction of jet fuel, and it’s far less price volatile. Airports also benefit: chargers are cheaper and simpler than the sprawling supply chains of fuel trucks, tanks, and underground pipelines

Lower maintenance costs: They have less moving parts. That means less to wear out, less to stock, and less downtime.

Lower noise pollution: Allows night operations that abide by curfews, effectively creating new capacity at constrained airports

All of this adds up to transforming the economics of incumbent regional air carriers or their potential usurpers. It also creates new markets that aren’t viable with conventional airplanes.

But none of that matters if electric airplanes can’t scale their payloads by an order of magnitude. Is that possible?

The One Number Driving Electric Flight

Electric aviation has made progress across the stack — from airframes to motors, electronics, and compute. But the chief bottleneck to carrying larger payloads remains the same: batteries.

It’s tempting to think the answer is simply adding more of them, or upgrading to bigger ones. But aviation doesn’t work that way. Airplanes are brutally weight-sensitive: every extra kilogram of battery requires more energy just to lift itself. Airlines already live this paradox when they burn fuel to carry fuel.

The real constraint isn’t battery size, it’s battery density. To scale electric airplanes, we don’t need batteries that are big enough, we need batteries that are dense enough.

Energy density is measured in Wh/kg (watt-hours per kilogram). Think of it as the electric equivalent of miles per gallon. The higher the number, the more useful your airplane becomes: it can carry more payload, fly farther, or sometimes do both.

Battery Systems Determine Energy Density

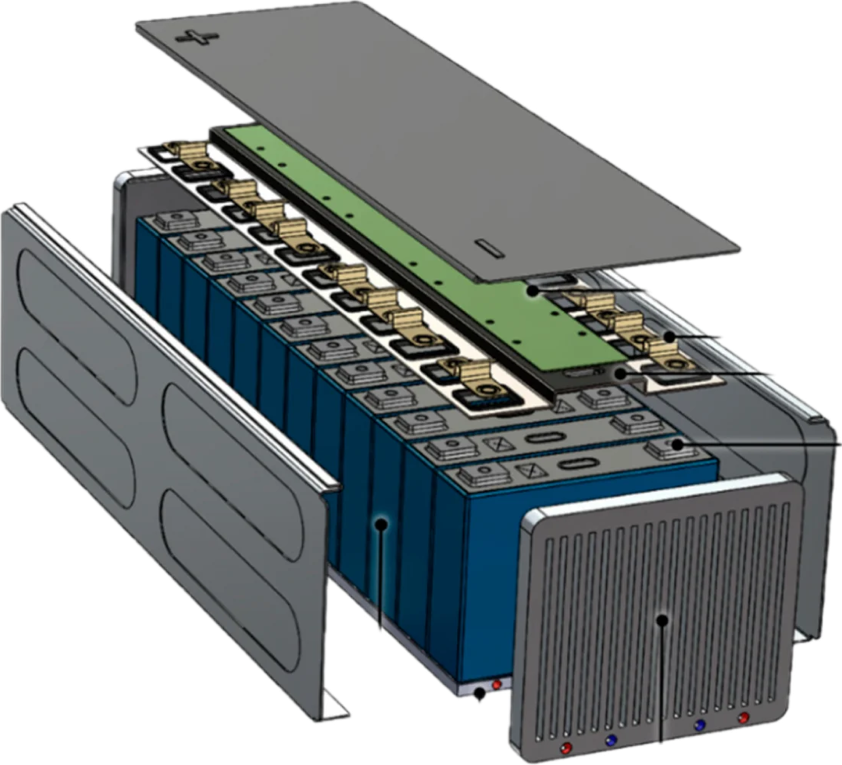

We don’t just strap loose batteries into an airframe and expect it to fly. Individual cells are assembled with cooling, casing, and wiring into a battery pack, the unit that actually powers an aircraft.

Here’s the catch: a pack’s energy density is always lower than that of the cells inside it. Cells in a lab can hit ~500 Wh/kg, but once you add the hardware that makes them safe and usable, the real-world pack may be 30–50% lower.

Still, packs are systems — and systems can be improved, both in the lab and in the field:

In the lab, improvements come from:

Developing better cells (e.g. silicon anodes, lithium-metal, solid-state)

Optimizing pack architecture with lighter materials and fewer structural overheads

Smarter battery management systems that squeeze more usable energy out of each cycle

In the field, improvements come from:

Standardizing pack formats so future chemistries can “drop in” without a full redesign

Volume production that justifies more advanced and costly materials

Faster iteration loops as real-world flight data feeds directly into the next design

Together, these lab and field improvements steadily raise the Wh/kg of packs — and every incremental gain opens the door to larger, more capable electric aircraft.

How Big Can Electric Planes Really Get?

Today’s cutting-edge is a 250 Wh/kg “pack-level” system, like the BETA Alia CX300 from last week’s article. That’s a huge leap from where we started not long ago. In the early 2010s, prototypes like the Pipistrel Taurus Electro were closer to 100 Wh/kg, enough to power a 2-seat motor glider for about 30 minutes.

Through the following decade, pack energy density climbed toward 200 Wh/kg, enabling the Pipistrel Velis Electro — the world’s first fully certified electric trainer.

Now, just five years later, we’ve reached 250 Wh/kg, enough to lift 6–9 people (including pilots) depending on range and configuration. Progress may feel slow, but it’s undeniable. And crucially, it’s happening in years, not decades.

So where do we go from here? The accelerant will be production aircraft: once airplanes like the CX300 are flying revenue missions, they force suppliers, regulators, and operators into a cycle of standardization, scaling, and iteration that speeds up innovation.

If energy density keeps improving at roughly the pace we’ve seen (about 13 Wh/kg per year) the curve looks something like this:

2028–2030: 275 Wh/kg → 9-seaters

2030–2033: 300 Wh/kg → 12-seaters

2035–2038: 350 Wh/kg → 19-seaters

2040–2045: 400 Wh/kg → 30-seaters

It’s a long runway to get from gliders to true regional aircraft. But the trajectory is clear: each incremental boost in density pushes electric aviation up a size class.

The Ceiling on Batteries

The simple forecast above is normalized to BETA’s CX300 mission profile. We can trade-off seats for range, or explore hybrids. Hybrids can extend endurance, but they also erode many of the benefits that make all-electric attractive in the first place.

Meanwhile, other technologies are maturing in parallel. I call it the next-gen triad:

Batteries

Hydrogen

SAF (Sustainable Aviation Fuel)

Realistically, we need all of them combined to build a big enough envelope around all of commercial aviation. That’s because the current battery chemistry sets a hard ceiling at around 450–500 Wh/kg at the pack level. That makes long-haul electric a pipe dream.

But for regional flying, batteries are not just viable, they’re inevitable.

I’ll be exploring the other two pillars of the triad in future articles, so be sure to subscribe to get them!